StewMac’s engineered MDF foundation aligns raw materials with squared precision, its rigid structure a silent tribute to the necessity of a stable core.

Retracting thumbscrews remove hardware obstructions, allowing the builder to focus on the internal geometry, akin to clearing the mind to better hear one’s purpose.

Yet, even as the contoured caul protects the instrument’s delicate surface, the question remains whether this fixture is merely a tool or a required foundation for the work ahead.

Key Takeaways

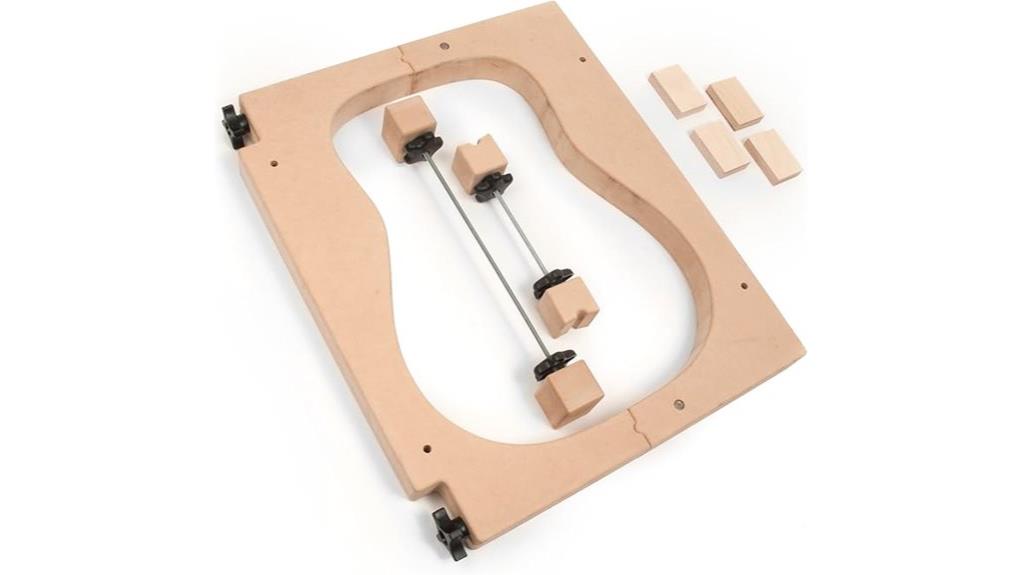

- Constructed from thick, warp-resistant MDF, this rigid mold provides a stable foundation for building instruments with proper geometry.

- Pivoting thumbscrews retract fully into the frame, removing external obstructions to facilitate a smoother and more efficient assembly path.

- Precise alignment features cradle the waist, neck, and tail blocks, ensuring every side remains squared while eliminating guesswork.

- The design includes contoured hardwood cauls that gently cradle curves to secure linings without marring the instrument’s surfaces.

- This reliable investment validates accuracy, making it an essential and silent partner for building classical guitars and StewMac kits.

Why You Need a Guitar Body Mold for Accuracy

While the untrained eye might simply see a framework of 2-inch thick, non-warping MDF engineered wood, the StewMac Acoustic Guitar Body Mold represents the foundational discipline required to transform chaotic raw materials into an instrument of divine resonance. This fixture, born from shop foreman Todd Sams’ innovative design, securely cradles the guitar’s waist, neck, and tail blocks, ensuring every side remains squared. False

While novices often search for the best acoustic guitars for beginners, luthiers understand that precision is paramount. Such precision, akin to the unwavering integrity one offers in service, eliminates guesswork during lining installation. By holding the form true, the builder may focus entirely on their craft, creating an instrument destined to serve others through music.

How the Internal Thumbscrews Improve Clamping Efficiency

The ingenious integration of pivoting threaded thumbscrews, which retract fully into the grooved ends of the mold, offers a seamless path to structural integrity, unburdened by the friction of external hardware.

This feature facilitates a smoother assembly process, removing obstructions to allow the builder to focus entirely on their craft.

Design Precision: Non-Warping MDF and Contoured Cauls

Structural integrity lies at the heart of the StewMac Acoustic Guitar Body Mold, achieved through the use of strong, non-warping MDF engineered wood that guarantees the assembly remains perfectly squared. This steadfast foundation offers stability, a reminder that true strength supports others best when unyielding.

Complementing the frame, contoured hardwood cauls cradle the instrument’s curves with gentle pressure, ensuring linings adhere faithfully without marring the surface. This careful attention to detail mirrors the patience required in service, where protective guidance fosters growth. Builders seeking to honor their craft will find these tools essential for creating resonant, enduring instruments of beauty.

Will This Mold Fit Your StewMac Guitar Kit?

Compatibility serves as the bridge between potential and realization, perfectly aligning this mold with StewMac’s sold-separately Guitar Kits, much like how shared beliefs unite a community in common purpose.

This alignment, utilizing the Model 4738’s rigid MDF frame and pivoting thumbscrews, offers the builder a secure foundation, akin to the unwavering support found in service to others.

The contoured hardwood cauls and notched waist blocks facilitate unobstructed assembly, ensuring the instrument’s integrity remains intact. By accommodating necessary side strip clearance, the mold functions as a silent partner, guiding the craftsman’s hand toward creating a vessel of music.

Is the StewMac Acoustic Body Mold Worth the Cost?

Evaluating the financial outlay for the Model 4738 requires looking beyond the price tag to the intrinsic value of precision, a concept that resonates deeply with the craftsman seeking order in a chaotic world.

The 2-inch MDF structure, a steadfast foundation, eliminates the anxiety of misalignment, akin to finding spiritual grounding amidst life’s turbulence. Pivoting thumbscrews, tucking internally to allow unobstructed service, mirror the humility required to serve others without obstruction. This tool validates the investment through reliability, ensuring every assembly honors the recipient with perfection, and proving that true craftsmanship is an act of devotion. This high level of accuracy is particularly critical when constructing best classical guitars, as they rely heavily on proper geometry for tone. Just as precision defines the acoustic realm, players searching for the amplified equivalent often debate the best electric guitars for their sonic versatility.

Frequently Asked Questions

Does This Mold Require Assembly Upon Arrival?

The product arrives fully assembled. This thoughtful design allows luthiers to immediately dedicate their time to the craft of guitar building. Serving both the instrument and its future owner by streamlining the preparation process.

Can the Mold Be Used for Non-Dreadnought Body Shapes?

A luthier building a parlor guitar would find this specific mold incompatible, as it is engineered solely for the dreadnought silhouette.

Its precise contours facilitate dedicated service for that specific body shape, ensuring accurate construction.

What Are the Exact Weight and Shipping Dimensions?

The specific shipping weight and dimensions are not listed in the provided details.

A standard two-inch thick MDF mold is a substantial item, suggesting the package would be heavy and correspondingly large. Users should prepare for a sizeable delivery.

How Do I Claim or Use the Product Warranty?

To seek protection for this tool, users must follow the linked pathway, a digital guide ensuring continued service. This act safeguards their future labors, allowing the maker to focus on giving life to music.

Is the MDF Material Sealed Against Humidity Changes?

Engineered wood materials are inherently susceptible to humidity. StewMac documentation does not specify sealing.

Users must maintain a stable environment or apply a protective sealant to prevent warping, ensuring the tool reliably aids future projects.

Conclusion

Ultimately, this rigid MDF foundation acts as the silent luthier’s steadfast conscience, anchoring the instrument’s geometry, akin to the unwavering values that ground a spiritual life. The retractable thumbscrews remove worldly obstructions, allowing the builder to focus entirely on creation, a reminder that precision is a form of devotion.

Through contoured cauls that protect the wood’s delicate surface, this mold does not merely assemble parts, but shepherds resonance, proving that true harmony requires both structural integrity and a faithful vision.